Metal wire craft

Aluminum, Stainless Steel, Carbon Steel, Copper, etc.

Surface treatment:

Plating Zinc/ Tin/ Ni/ Electro-Nickel/ Gold/ Silver, powder coating, paint, , etc

Equipments: punching machines,lathes,bending machine,cutting machines, dotters, Looping machines,straighten machines,pipe cutter,welding machines and so on.

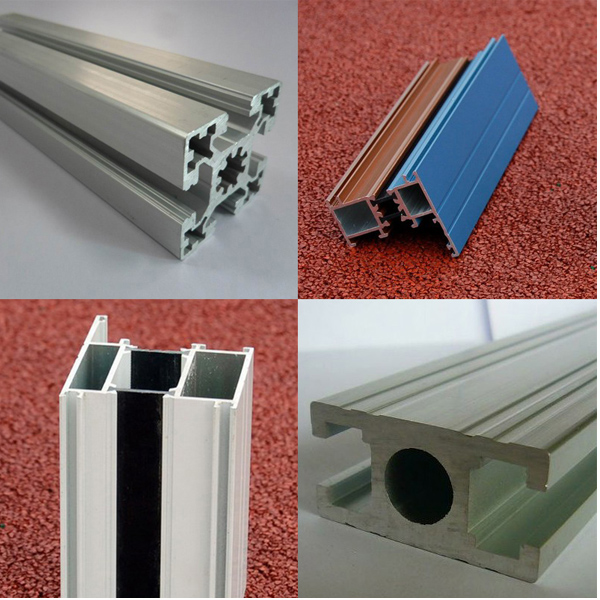

Aluminum Extrusion

Aluminum extrusions:

Aluminum extrusions are shaped pieces of aluminum produced by heating aluminum blocks and pushing them through a die shape to create specific patterns. Extrusions can be manufactured in many sizes and in almost any shape for which a die can be created. Extruded aluminum offers durability and structural strength, and it is fully recyclable.

The material we can produce:

6063, 6061, 6060, 6082 and 7075 aluminum alloy

Surface treatment:

Anodizing, mechanical polish, sandblasting,mill finish,etc.

Metal spinning

Metal spinning:

Metal spinning is now a cost-effective option for both medium and high volume production, which is a forming process that produces hollow parts that are typically circular in crosssection. The metal spinningprocess starts with a flat metal disc (blank), then the metal disc is rotated on a lathe. This rotating blank is pressed against a tool (chuck mandrel) that duplicates the interior of the

The material we can produce:Steel, Stainless Steel, Aluminum, Brass, Copper

Surface treatment:

Paint, Polishing, Zinc plated, Nickel plated, Bronze plated, Silver plated and so on.

Sand Casting

Sand casting:

Sand casting:

Sand casting

is used to make large parts (typically Iron, but also Bronze, Brass, Aluminum). Molten metal is poured into a mold cavity formed out of sand (natural or synthetic).

Surface treatment:

Sand blasting, polishing, Electroplating, powder coating, oxidation (black and nature), passivation,etc.

Die Casting

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from nonferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter and tin based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

The casting equipment and the metal dies represent large capital costs and this tends to limit the process to high volume production. Manufacture of parts using die casting is relatively simple, involving only four main steps, which keeps the incremental cost per item low. It is especially suited for a large quantity of small to medium sized castings, which is why die casting produces more castings than any other casting process.Die castings are characterized by a very good surface finish (by casting standards) and dimensional consistency